Lab Inventory Software – Comprehensive Feature Guide

Summary

Lockbox Lab Inventory Software offers a comprehensive solution for laboratories to optimize inventory tracking, streamline workflows, and enhance overall operational efficiency. It includes detailed management of consumables and reagents, enabling users to record the name, description, price, supplier, etc. For physical inventory, the module tracks detailed storage position/location information and inventory statuses, which include received, quarantined, available, reserved, consumed, expired, and unavailable. Lockbox Inventory Management accommodates various material types, including kits, discrete/countable inventory, multi-use, and measurable items.

Key Features

- Comprehensive inventory tracking for reagents, consumables, and lab supplies

- Cycle Counting

- Lot number traceability linking each sample and protocol back to the specific inventory used

- Item master details including name, description, supplier, and catalog number

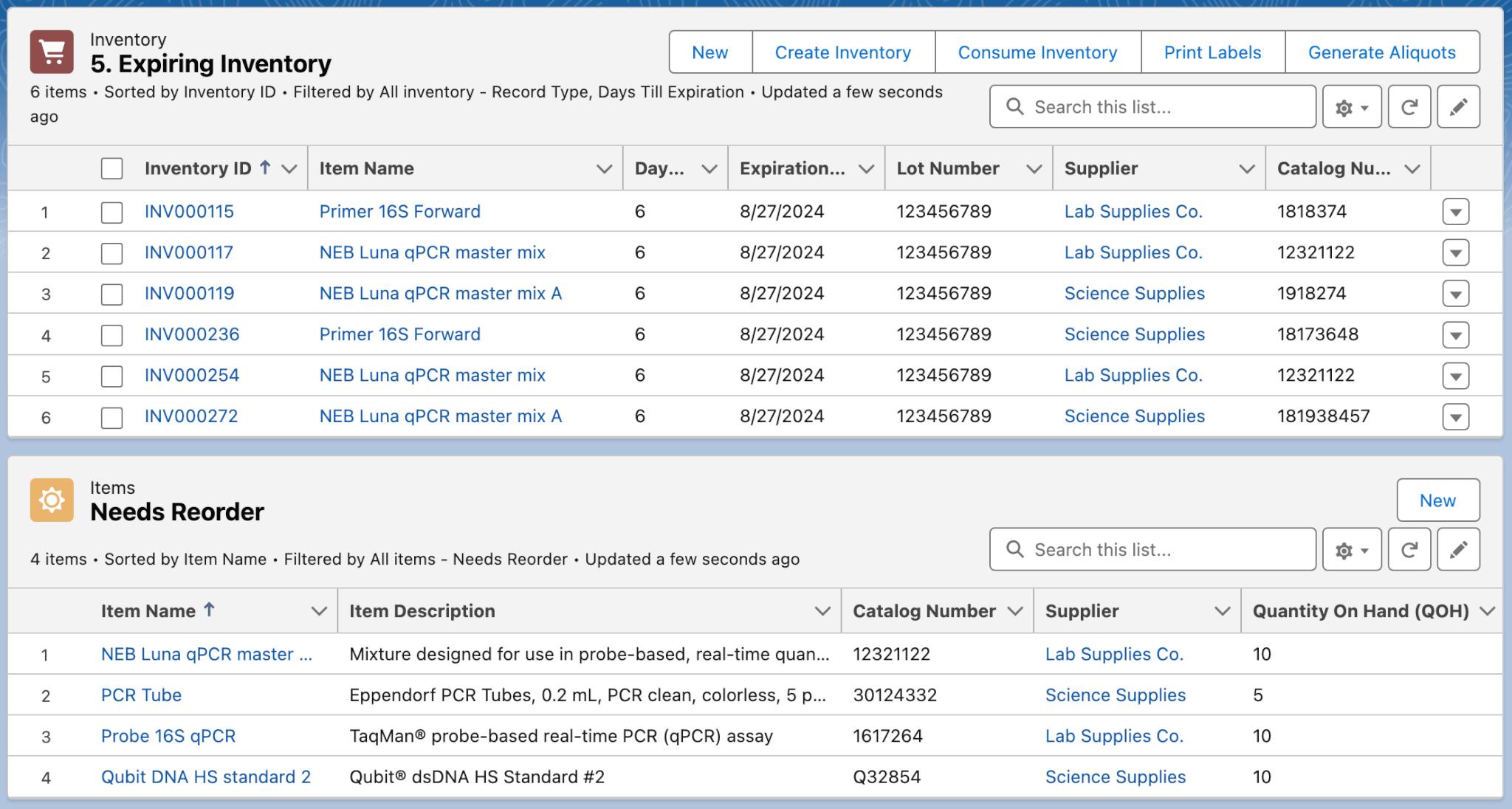

- Expiring inventory alerts

- Re-order reminders

- Create, print, and scan barcode labels to efficiently create inventory records and track inventory consumption

- Comprehensive reporting and analytics

- Integration with other systems, including billing and ERP systems

- Multi-site and remote access capabilities

Why do Labs Need an Inventory Management System?

Effectively managing your lab’s inventory is essential for successful lab operations, but it comes with its own set of challenges. One of the main issues is the complexity of tracking a wide variety of materials, including kits, reagents, and consumables, each with specific storage requirements, expiration dates, and usage protocols. Mismanagement of inventory stock can lead to expired or contaminated materials, resulting in wasted resources and potential safety hazards. Discrepancies, like lost or misplaced inventory, can disrupt laboratory workflows and potentially delay critical experiments and research. Without an efficient inventory management system, laboratories may struggle to ensure that their lab supplies are tracked from creation to consumption, stored properly, and available when needed. Lockbox Inventory Management provides all the necessary tools to track inventory usage and manage inventory processes. In this article, we discuss the key features of Lockbox Inventory Management that enable you to run an efficient laboratory.

Inventory Tracking for Reagents and Lab Supplies

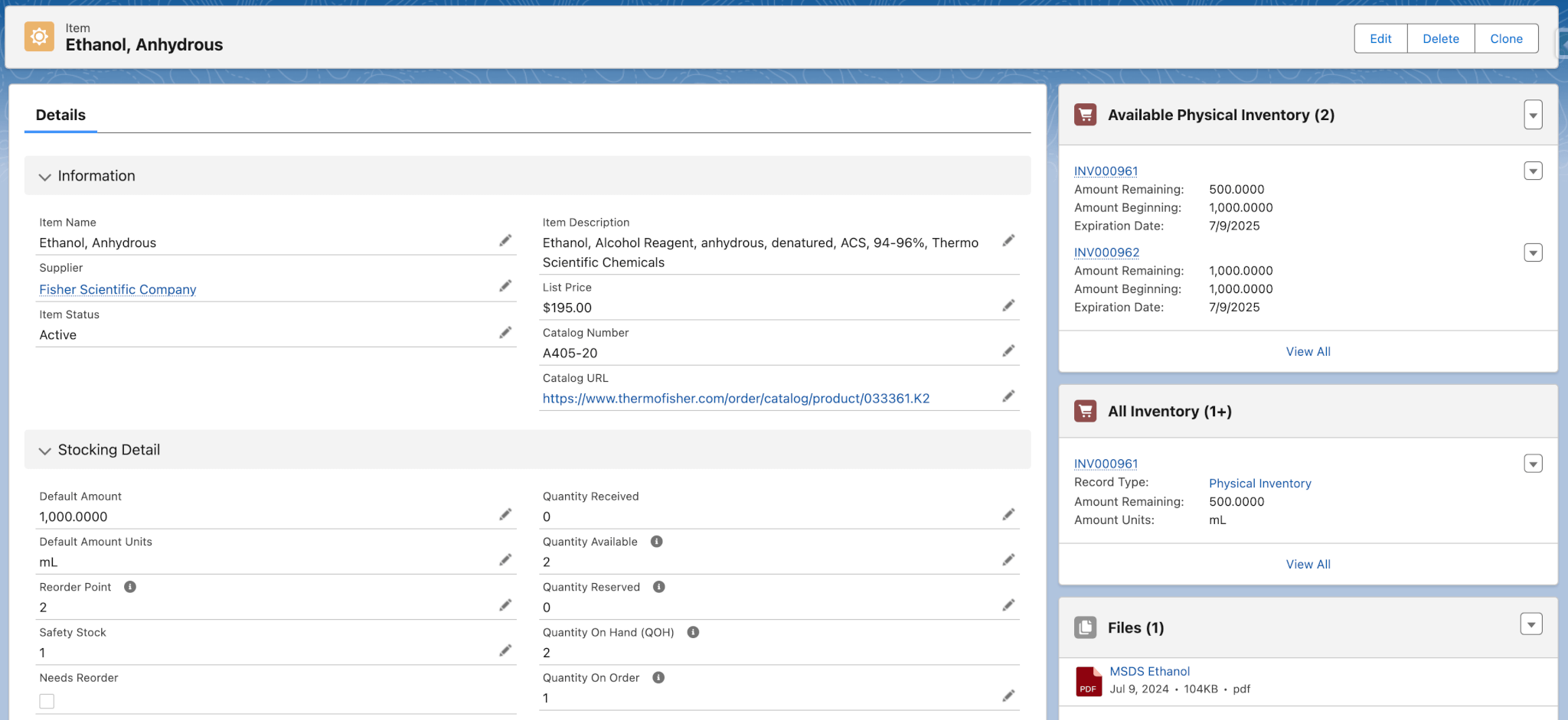

Lockbox Inventory Management enables you to capture detailed information about each item in your inventory, such as the item’s name, description, supplier, price, and catalog number. This helps lab managers streamline the re-ordering process by tracking what has been ordered and where it came from. Lockbox Inventory Management supports various inventory types, including single-use materials like pipette tips, multi-use items like kits, measurable materials like chemicals, and batched items.

- Store detailed information about each item, including name, description, supplier, price, and catalog number.

- Track the quantity ordered, received, reserved, and available for each item.

- Set reorder points to automatically alert users when items are running low.

- Store files, such as Material Safety Data Sheets, for each item.

- Each inventory record represents a unique instance of an actual physical item.

- View a list of received, quarantined, available, reserved, consumed, expired, or unavailable inventory.

- Track the following types of inventory:

- Discrete inventory that can be used exactly once

- Multi-use inventory that can be counted and used a fixed number of times

- Measurable inventory, such as chemicals, that cannot be counted individually

- Batched items that include a parent component and sub-components

Real-Time Inventory Tracking

Full visibility into the status of inventory is essential for effective inventory management. Lockbox Inventory Management provides real-time tracking of available inventory quantities, expiration dates, and storage locations. This enables labs to save money by avoiding over-ordering and by prioritizing inventory usage according to expiration date.

- Expiration and transit monitoring

- Lockbox Inventory Management gives users real-time visibility of incoming inventory, outgoing inventory, and expiring inventory. Users can easily customize inventory report views to display the time to expiration, the number that will expire, or the already-expired inventory.

- Barcode scanners can help track inventory movement throughout the lab. Scanning inventory barcodes enables users to monitor where an item is located and who last used it.

- Cycle Count Feature for Reconciliation of physical inventory

- Using the new Cycle Count feature, users can easily enter existing physical inventory amounts and automatically adjust the existing quantities in Lockbox. This allows labs to true up actual physical inventory with what is reflected in the LIMS.

- View inventory information from a desktop, smartphone, or tablet (Android or iOS), as detailed in Multi-Site and Remote Access Capabilities below.

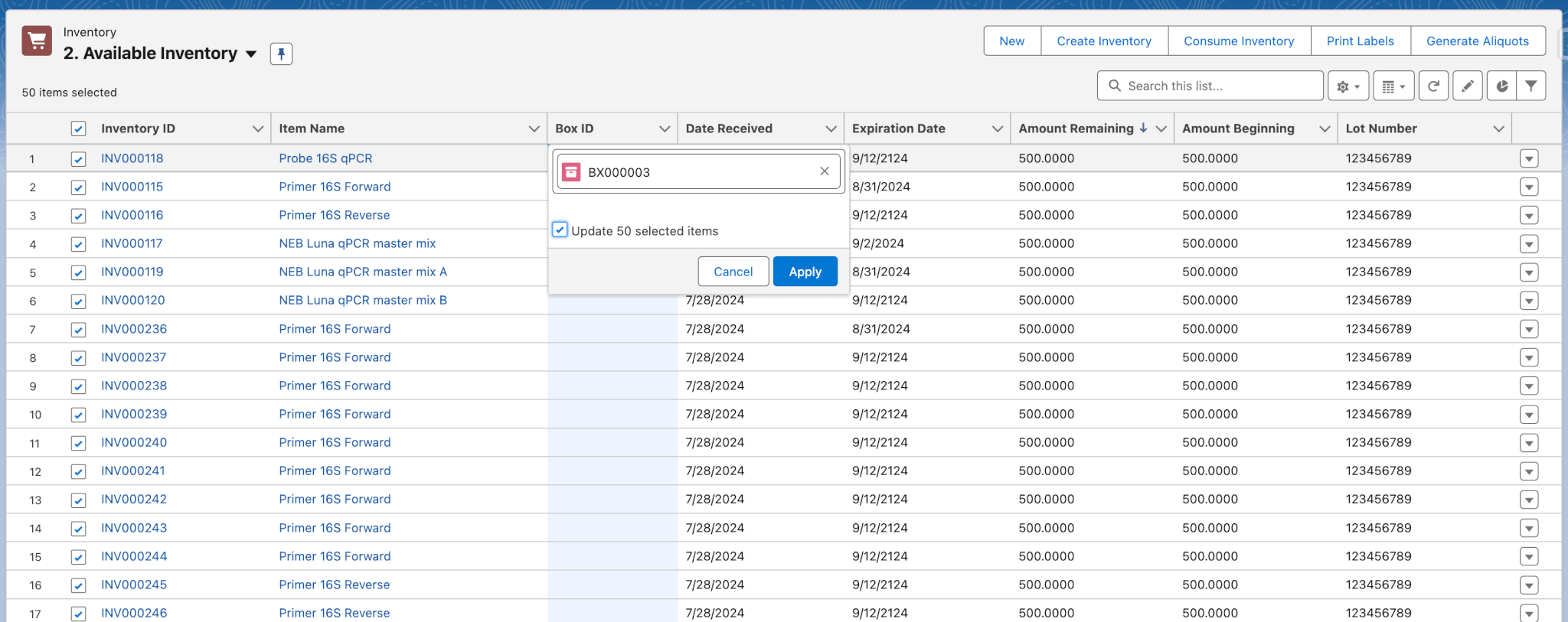

- Update multiple items or inventory at once through a bulk update feature.

Automated Alerts for Items that Need Re-Ordering

For labs with hundreds to thousands of items in their inventory, managing the expiration dates and stock levels for each item is incredibly difficult. Lockbox Inventory Management makes re-ordering and inventory management easier with automated alerts, such as email notifications, when inventory is running low or expiring.

- Receive an email or notification within Lockbox LIMSTM when inventory is low or about to expire.

- View stocking details to see current stock levels.

- Configure automated reminders to notify users when items need to be reordered or if items are below a stock threshold.

- Automatically capture important values such as today’s date when receiving new inventory.

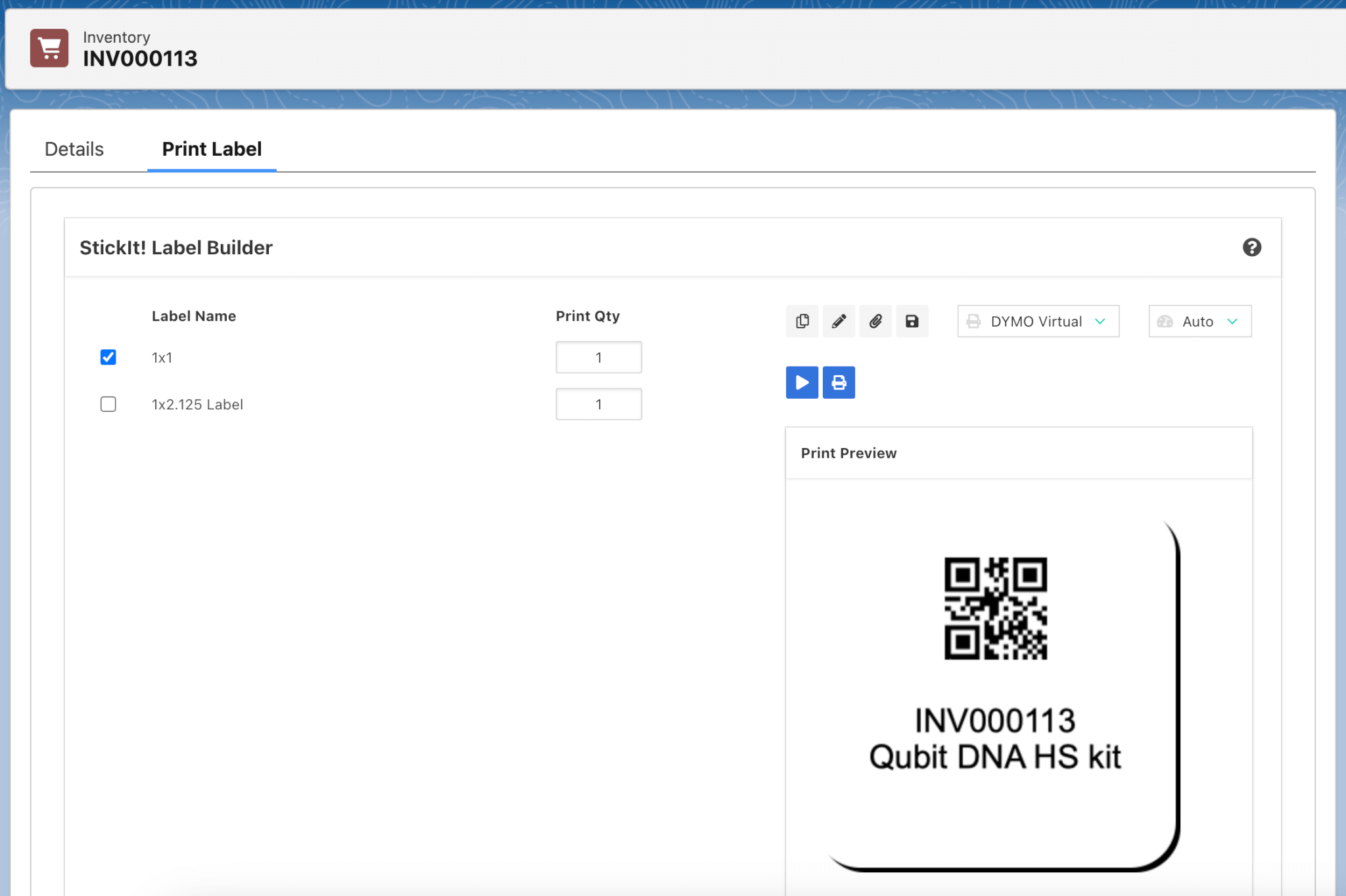

Inventory Barcode Printing and Scanning

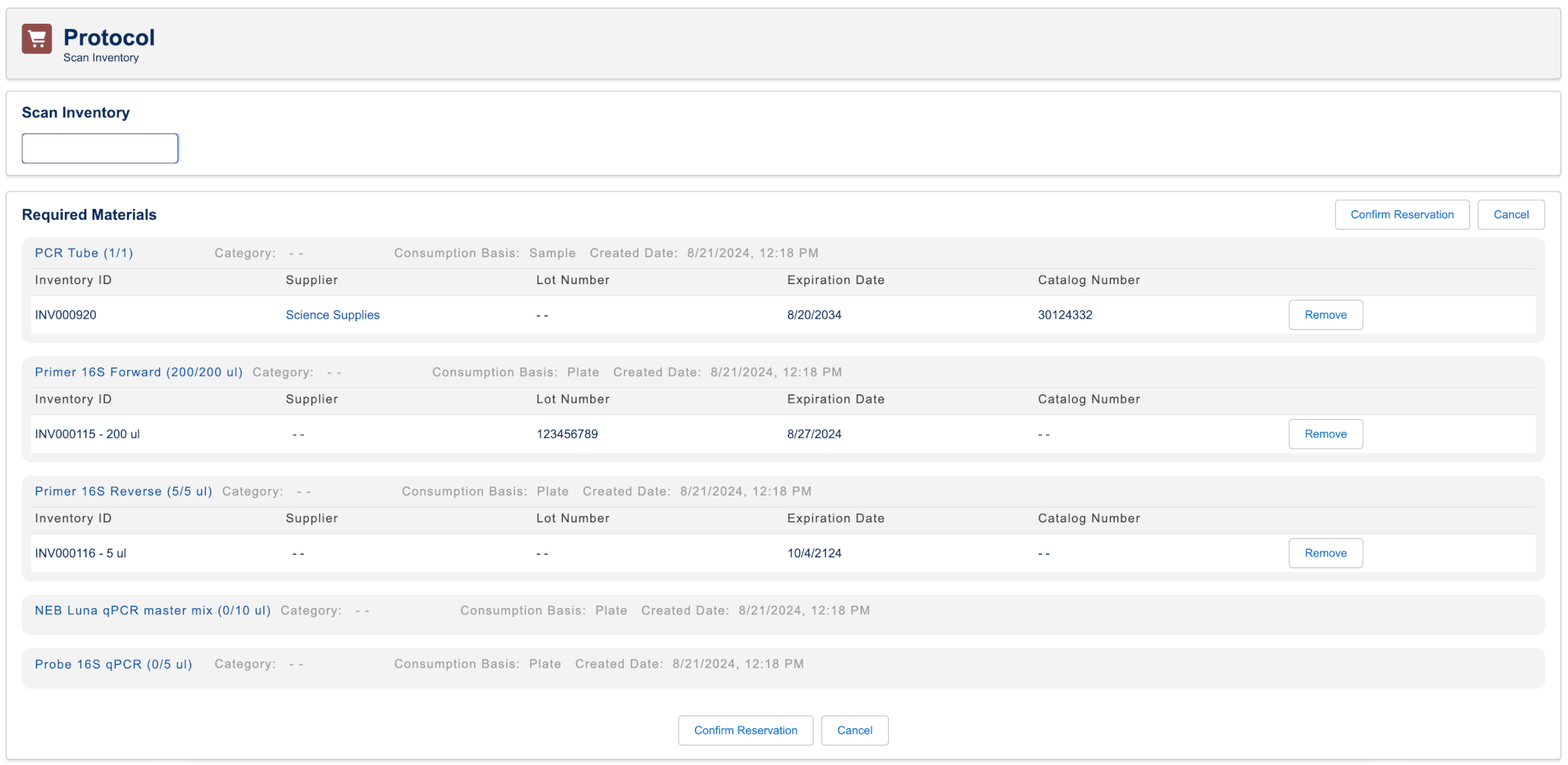

Lockbox Inventory Management can generate scannable barcodes for inventory items, enhancing the accuracy and efficiency of inventory tracking. Users can easily scan inventory barcodes to reserve inventory items for use in protocols.

- Create custom barcode labels with relevant information for easy identification and organization.

- Print to common printers, including Dymo and Zebra, ensuring seamless integration with your existing printing infrastructure.

- Barcode-labeled inventory can be scanned to reserve items for protocol execution.

- Automatically decrement inventory from your stock upon completion of the protocol.

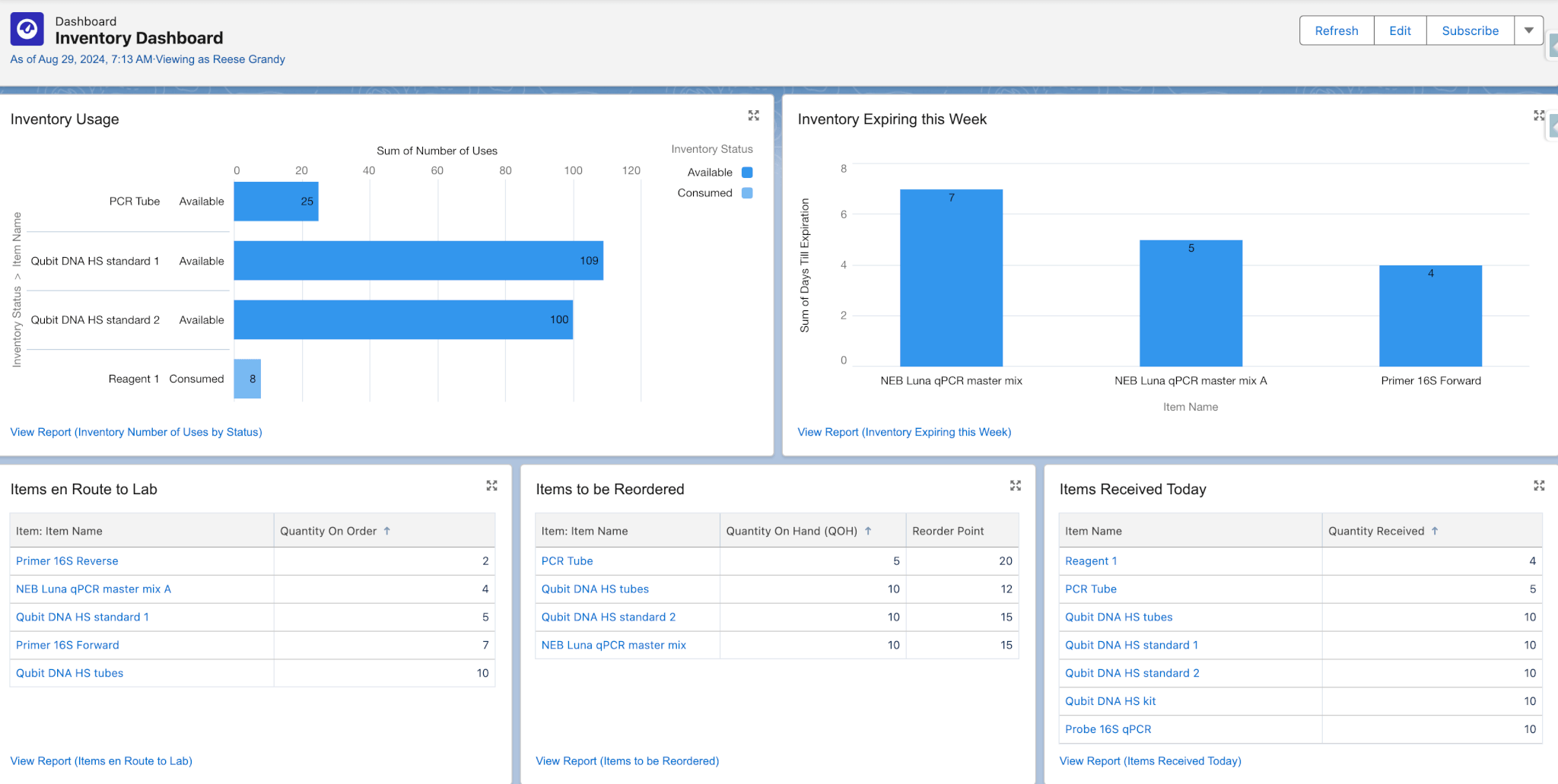

Comprehensive Reporting and Analytics

Lockbox Inventory Management has comprehensive reporting capabilities that simplify inventory management with tables, charts, and dashboards. Users can quickly generate reports to see key inventory metrics, such as items that have been ordered and inventory that is close to expiration.

- Generate reports of inventory nearing expiration.

- Generate a report of what items are en route to the laboratory.

- Create a shopping list and download a list of items that require reordering.

- Track spending and usage by item type, project, laboratory staff, time period, etc.

Customization and Scalability

Lockbox LIMS is highly customizable and our talented implementation team can tailor any aspect of Lockbox LIMS to meet your unique needs.

- Lockbox Inventory Management allows users to create and consume inventory in bulk with the click of a button.

- Nearly everything in Lockbox LIMS can be customized and changed by our team or yours, including reports, fields, and page layouts.

- Lockbox LIMS can grow with your laboratory, easily accommodating increased sample volume, new equipment, new workflows, or the need for additional Lockbox products. Lockbox LIMS can support your lab’s growth without major overhauls or costly upgrades.

- Lockbox LIMS can integrate with emerging technologies and adapt to evolving regulatory requirements, ensuring long-term viability without frequent replacements.

Integration with Other Systems

Lockbox Inventory Management works hand in hand with Lockbox QMS Quality Events, Lockbox LIMS Protocols and Procedures, and Lockbox LIMS Storage Management.

These seamless connections allow users to:

- Easily identify all items and lots involved in a deviation or occurrence, enabling identification of the involved samples or products, and facilitating requests for additional samples or recalls of products.

- Reserve, consume, and create inventory through protocol execution.

- Track the room, freezer, refrigerator, tank, incubator, rack, shelf, drawer, and box where inventory is located.

- Limit the time spent searching your laboratory for the inventory needed to complete a protocol or procedure.

- Like the other Lockbox products, Lockbox Inventory Management can easily integrate with third-party systems, including billing and ERP systems.

Secure and Compliant Data Management

Lockbox Inventory Management has all the safety and security measures of Lockbox LIMS, including:

- Login security and user authentication tools.

- User permissions and system access controls.

- Vulnerability monitoring tools.

- Complete audit trails.

- Data encryption.

- Approval processes.

- Lockbox Inventory Management is compliance-ready, enabling you to meet regulatory and compliance requirements.

Multi-Site and Remote Access Capabilities

Lockbox LIMS is completely responsive to any screen, enabling you to access your lab information from anywhere using a desktop, smartphone, or tablet (Android or iOS).

- Using Lockbox Inventory Management from a tablet or phone allows you to manage inventory in real-time by scanning barcodes and taking photos directly into Lockbox LIMS.

- Lockbox Inventory Management’s cloud-based data storage allows users to access inventory information from anywhere in the world. Users do not need to be on-site to access information stored in Lockbox LIMS.

Other applications are discussed in our article Essential LIMS Features for Effective Lab Inventory Management including:

- Tracking reagent lot numbers and expiration dates.

- Tracking the location of reagents in your lab.

- Recording the number of freeze/thaws.

- Calculating reagent usage to know when reagents are running low.

- Tracking individual kit components or ingredients used to prepare reagents in your lab.

- Tracking reagent suppliers and storing your quotes and invoices.

Conclusion

Lockbox Inventory Management enables laboratories to optimize the efficiency and accuracy of inventory tracking. It provides detailed management of consumables and reagents, with inventory status monitoring. The versatility of Lockbox Inventory Management enables laboratories to meet current operation needs and easily adapt to accommodate future requirements. This makes it an invaluable resource for any modern laboratory.

Are you interested in learning more? Watch our Inventory Management video to see some of the features discussed in this article. Contact us to book a demo or contact your Engagement Director to add the Inventory Management module to your existing Lockbox LIMS.