LIMS Inventory Management During Protocol Execution

Summary

Inventory management in a laboratory presents numerous challenges, such as running out of necessary supplies when attempting to execute a protocol, or discovering that essential inventory has expired or has been used by another team member. This article explores how integrating Lockbox LIMSTM Inventory Management with Lockbox LIMS Protocol Execution can address these issues, ensuring you have real-time access to available inventory and enhancing workflow efficiency.

Key Take Aways

- Streamline laboratory processes by automating status updates of inventory

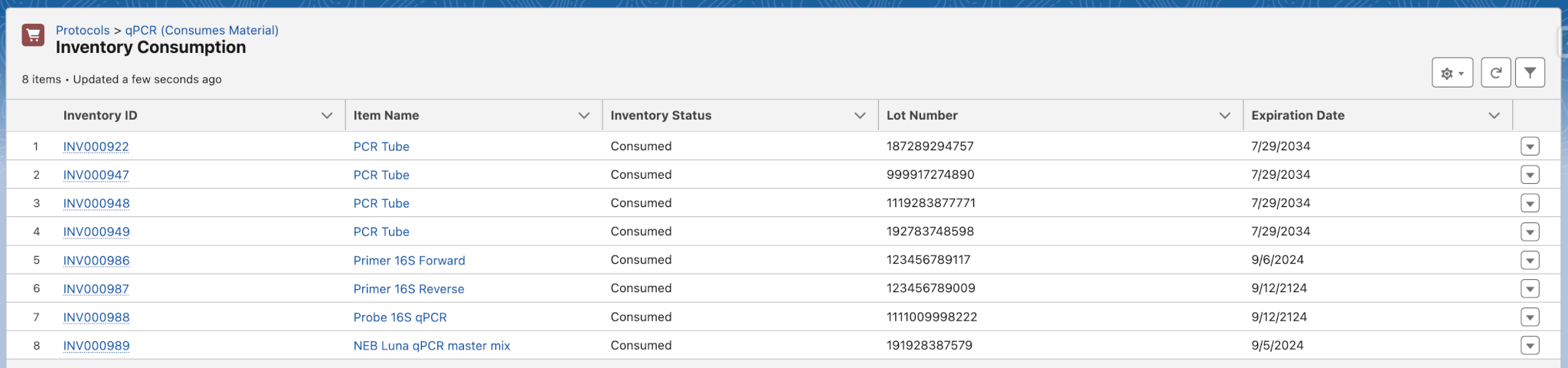

- Track inventory consumption during protocol execution

- Reserve inventory for protocols to prevent other lab members from using the reserved materials

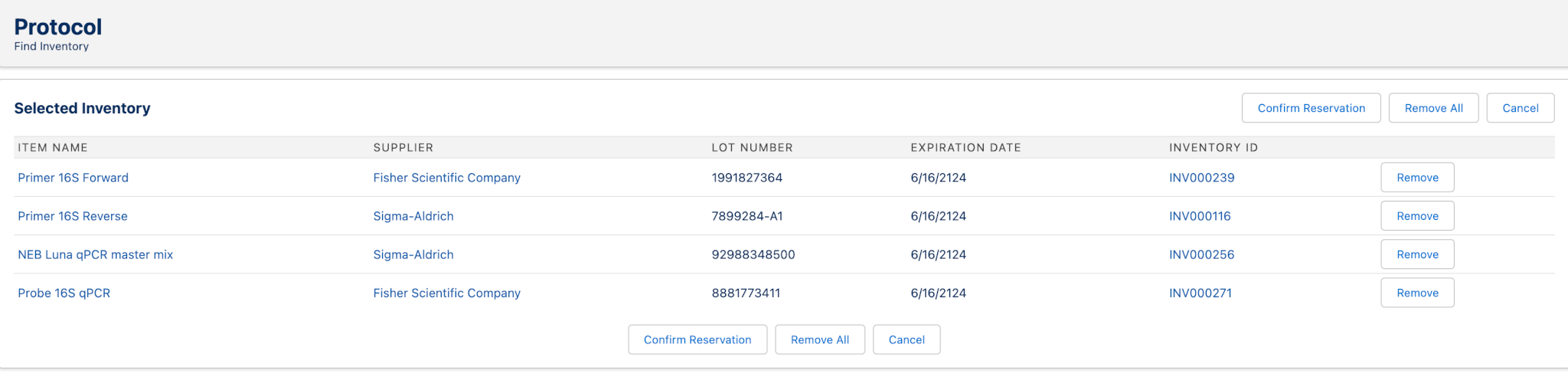

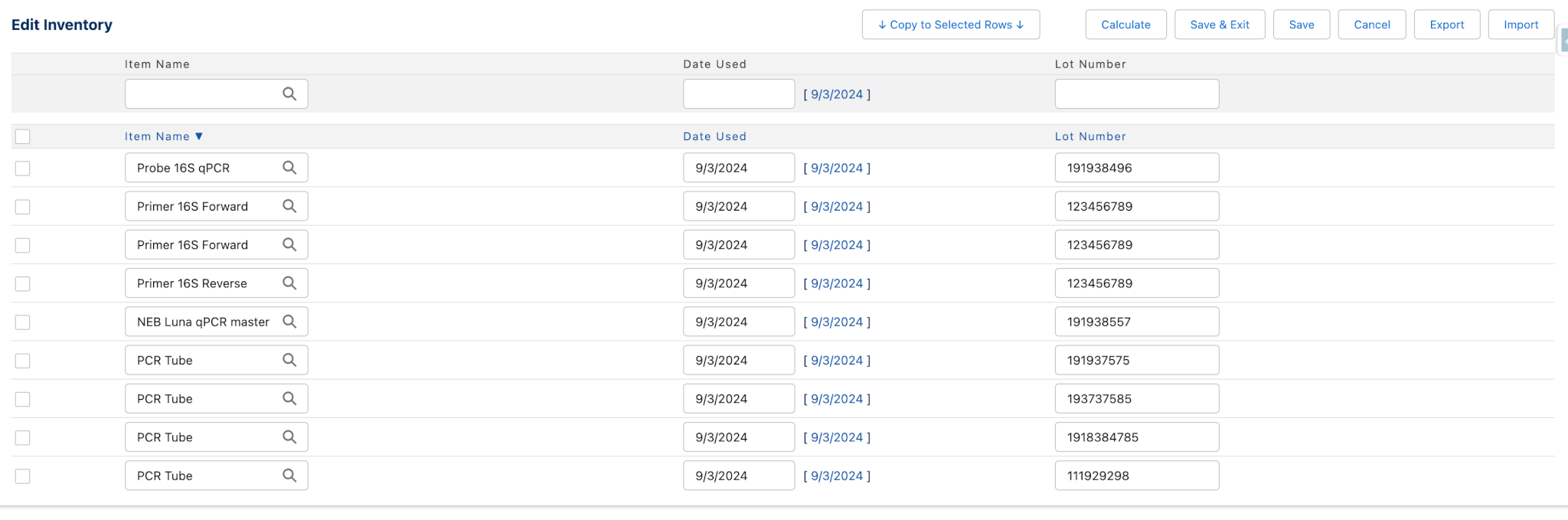

- Use the Find Inventory feature when initiating a protocol to select inventory by lot number and expiration date

- Use the Scan Inventory feature to record inventory consumption using scannable barcodes

- Automatically create inventory records when protocols result in net new materials such as reagents or manufactured products

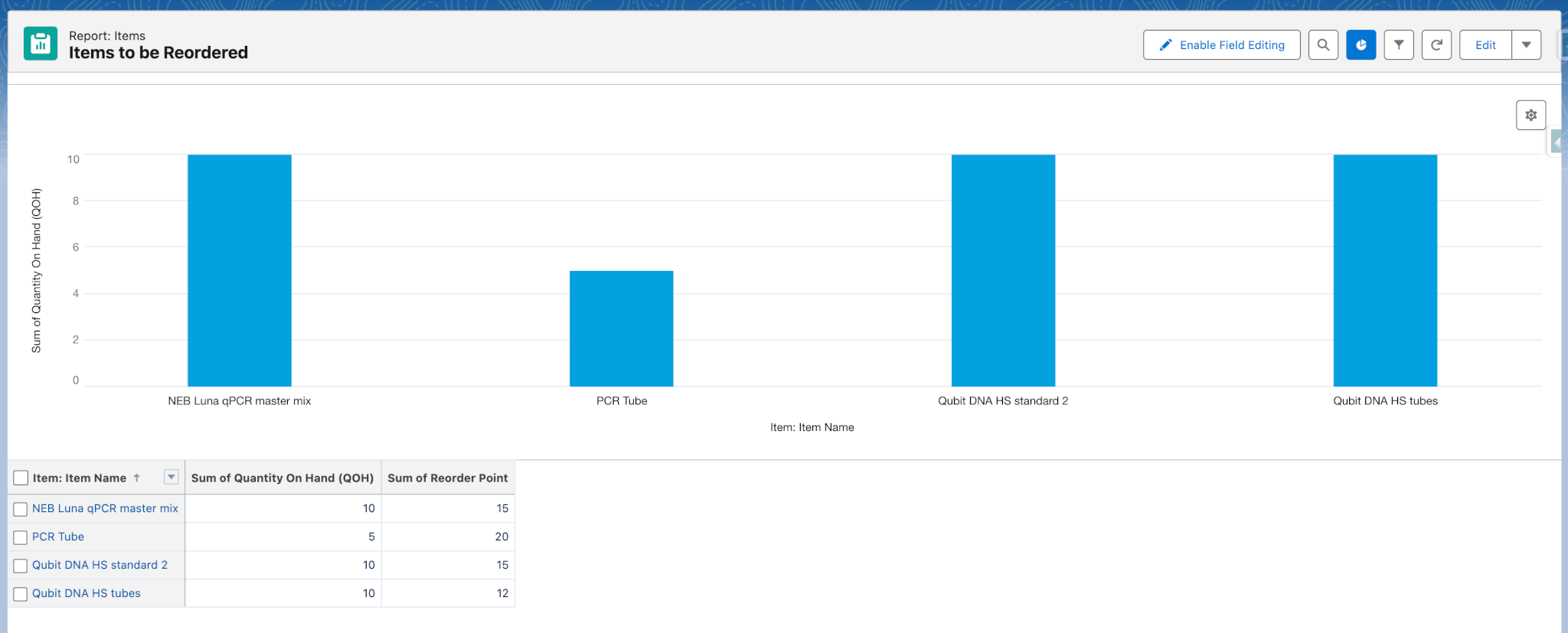

- Quickly generate reports to see key inventory metrics, such as items on order and inventory expiration dates

Why Should Laboratories Combine LIMS Inventory Management with Protocol Execution?

Using Lockbox LIMS Inventory Management with the Lockbox LIMS Protocol Execution module significantly enhances laboratory operations by automating routine tasks, reducing human error, and optimizing resource management. Lockbox ensures real-time inventory updates, accurate material selection, and efficient workflow management. Lockbox also supports regulatory compliance through detailed traceability and comprehensive documentation. The seamless connectivity between Lockbox Lab Inventory Management and Lockbox LIMS Protocol Execution module improves collaboration and communication among team members, ultimately leading to streamlined processes, reduced waste, increased cost efficiency, and higher precision in experimental outcomes.

Streamlined Laboratory Processes

Using Lockbox Inventory Management with Lockbox LIMS Protocol Execution module streamlines many laboratory processes and procedures. It eliminates the need to manually update inventory usage after workflow completion. Users can reserve items for use in a specific protocol execution, ensuring the necessary resources will be available. Lab managers can configure automated alerts of low stock and reorder points to ensure their technical staff always have what they need to complete their work.

- Automated Inventory Updates

- With Lockbox, inventory usage is automatically updated upon the completion of a protocol, procedure, or workflow. This eliminates the need for manual updates, reducing the risk of errors and saving time.

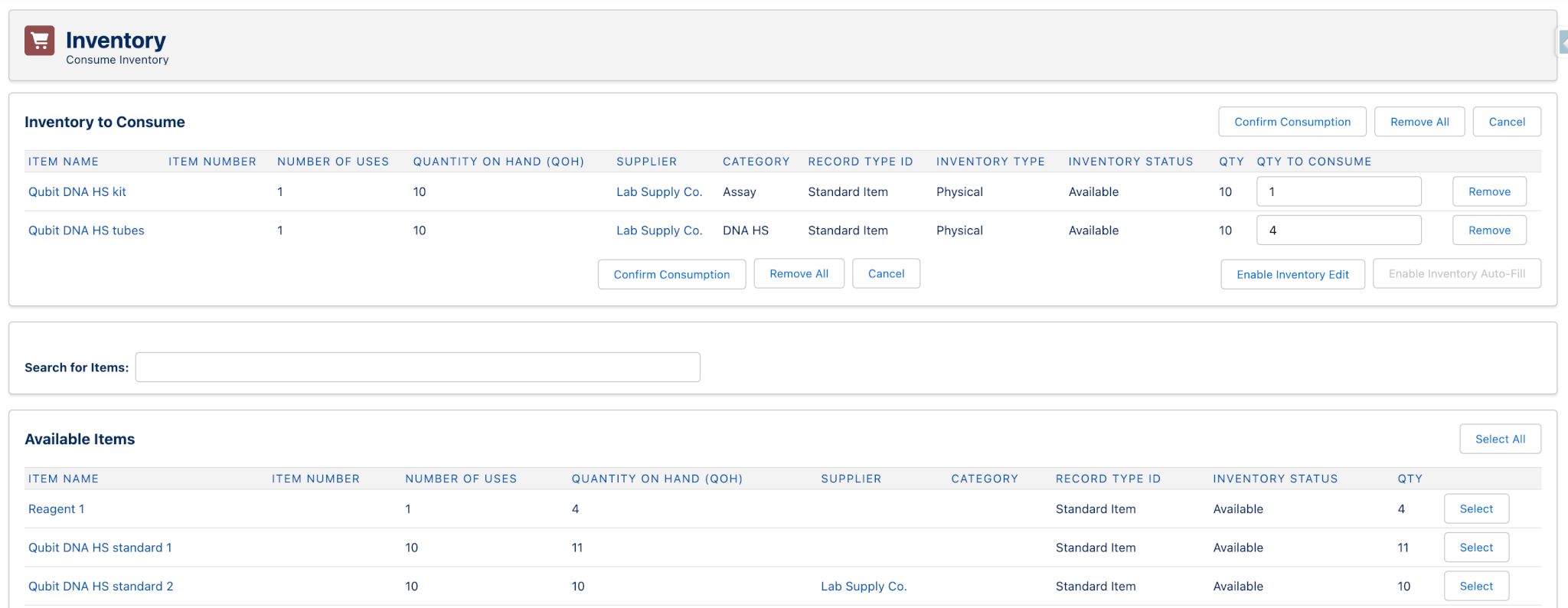

- Real-time Inventory Consumption

- Users can track inventory consumption during protocol execution. Users do not need to remember which materials they used and manually record the amount used. Lockbox automatically does this upon protocol completion, ensuring accuracy and efficiency.

- Inventory Reservation

- If a user knows they will need specific materials for an upcoming protocol, they can reserve inventory in advance. This feature prevents other lab members from using the reserved materials and gives laboratories more control over resource allocation to projects.

- Seamless Connections to Lockbox LIMS Modules

- Lockbox Inventory Management connects effortlessly with all Lockbox LIMS modules, enabling users to track samples, storage locations, and equipment all in one place.

- Automatic Inventory Selection for Protocols

- Lockbox users can utilize the Find Inventory feature when executing a protocol, to identify the best available inventory. Lockbox automatically selects the best option (e.g., partial containers or soonest to expire) to use in the protocol. Users are not bound to the inventory Lockbox chooses and can select a different option if desired.

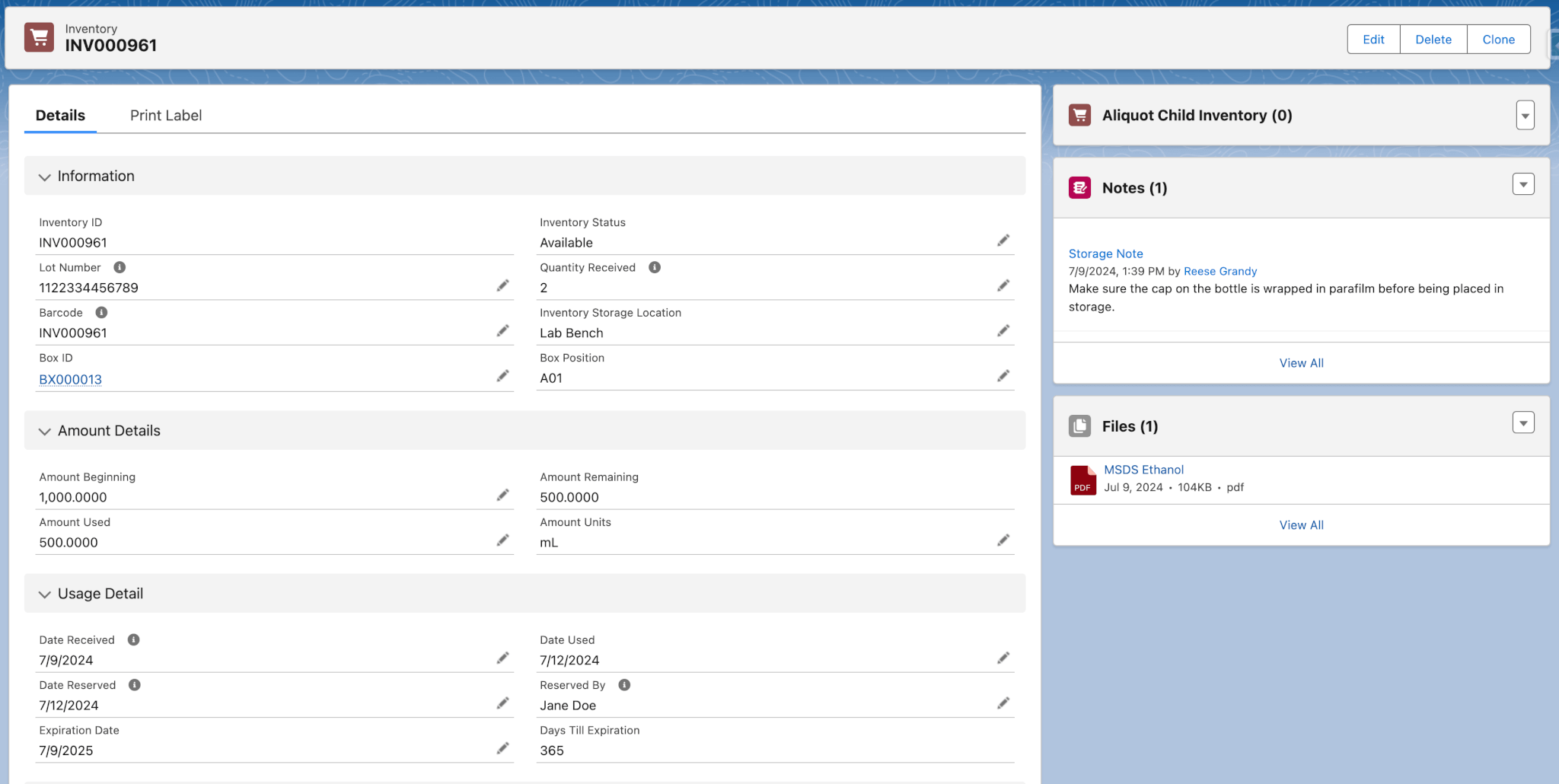

- Store Documents Related to the Item

- Important documents such as MSDS, COSHH labels, lot verification sheets, product information, etc., can be stored directly on the item record within Lockbox, eliminating the need for time-consuming searches. COSHH labels can be stored and printed from Lockbox for each hazardous reagent.

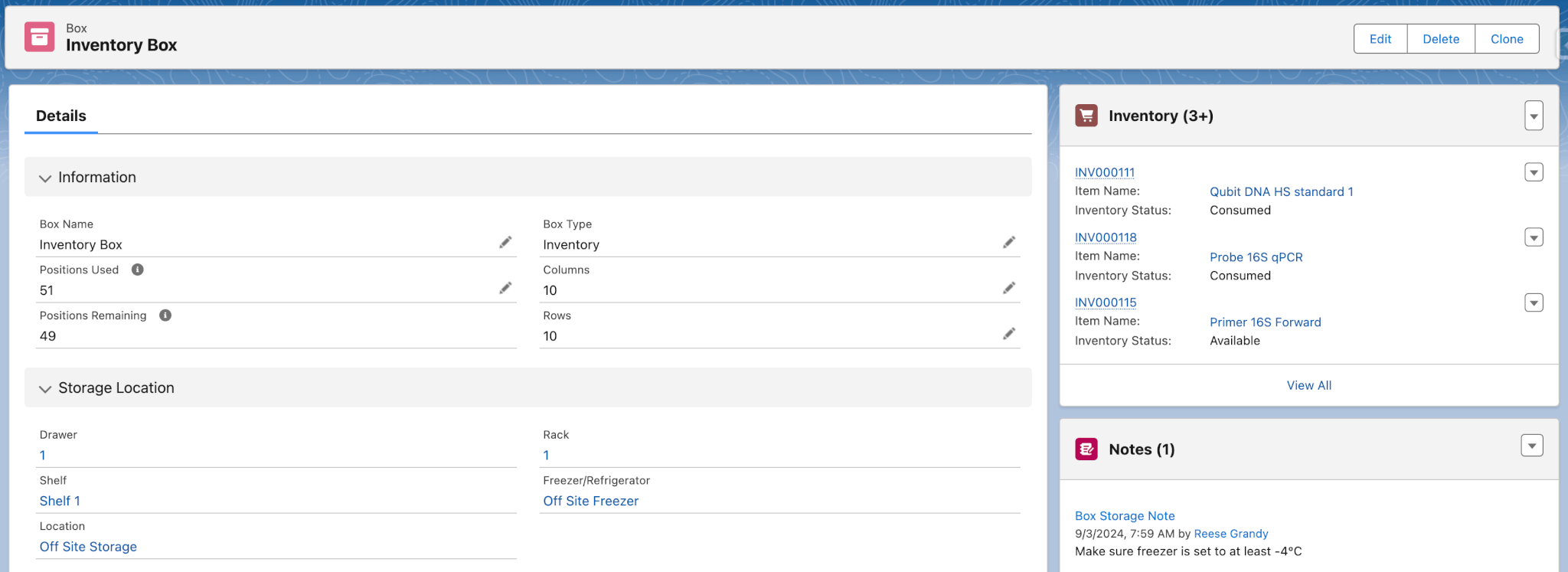

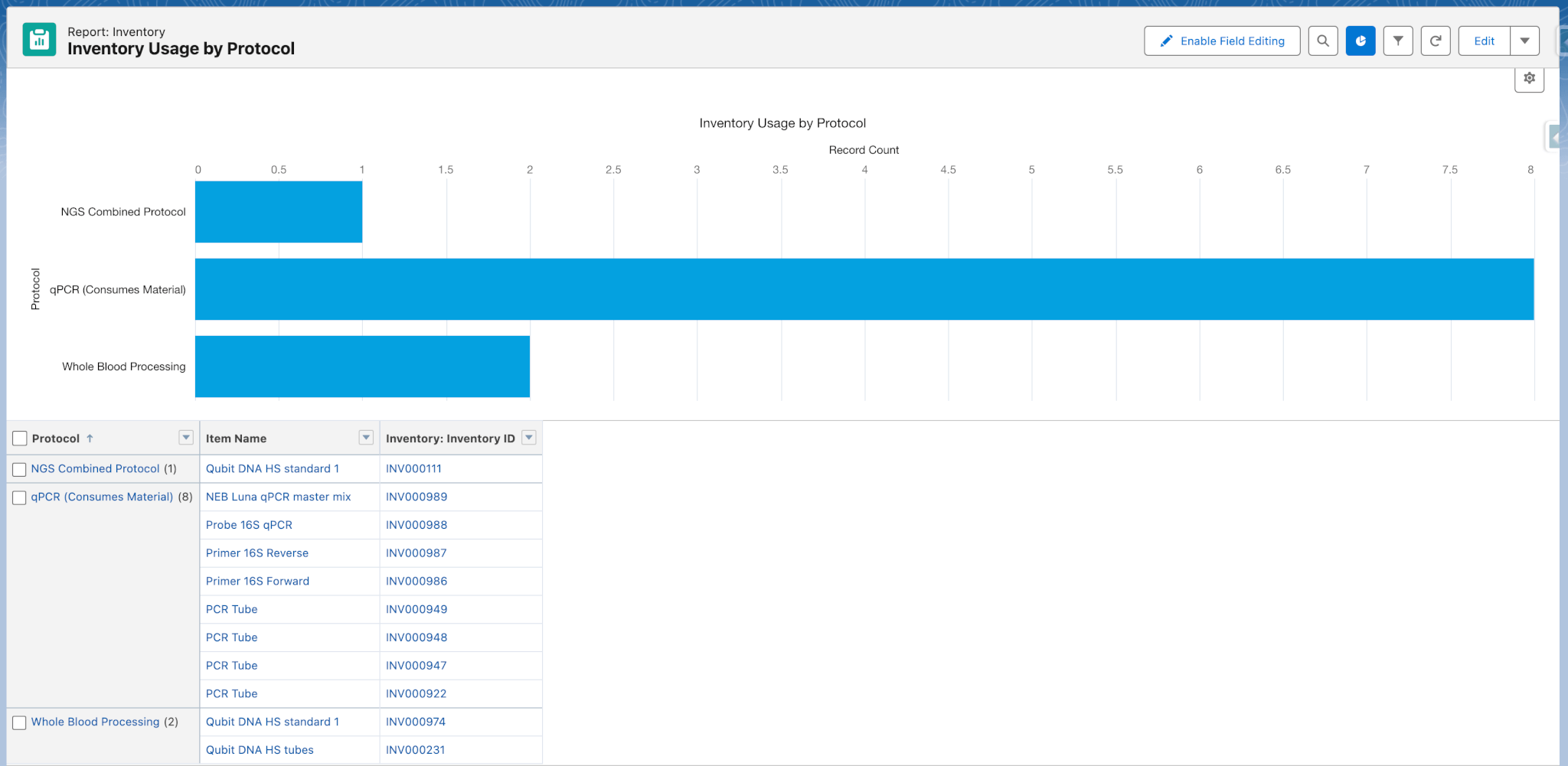

Enhanced Inventory Management Visibility and Resource Optimization

Lockbox users can create new inventory from protocols for use by another team or in another protocol. Lockbox Inventory Management seamlessly connects to all Lockbox LIMS modules, including Storage Management, allowing users to quickly locate items and inventory. Users can search for inventory in Lockbox by scanning an inventory barcode, lot number, or ID. The reporting capabilities of Lockbox make visualizing inventory usage, inventory expiration status, and inventory availability a breeze.

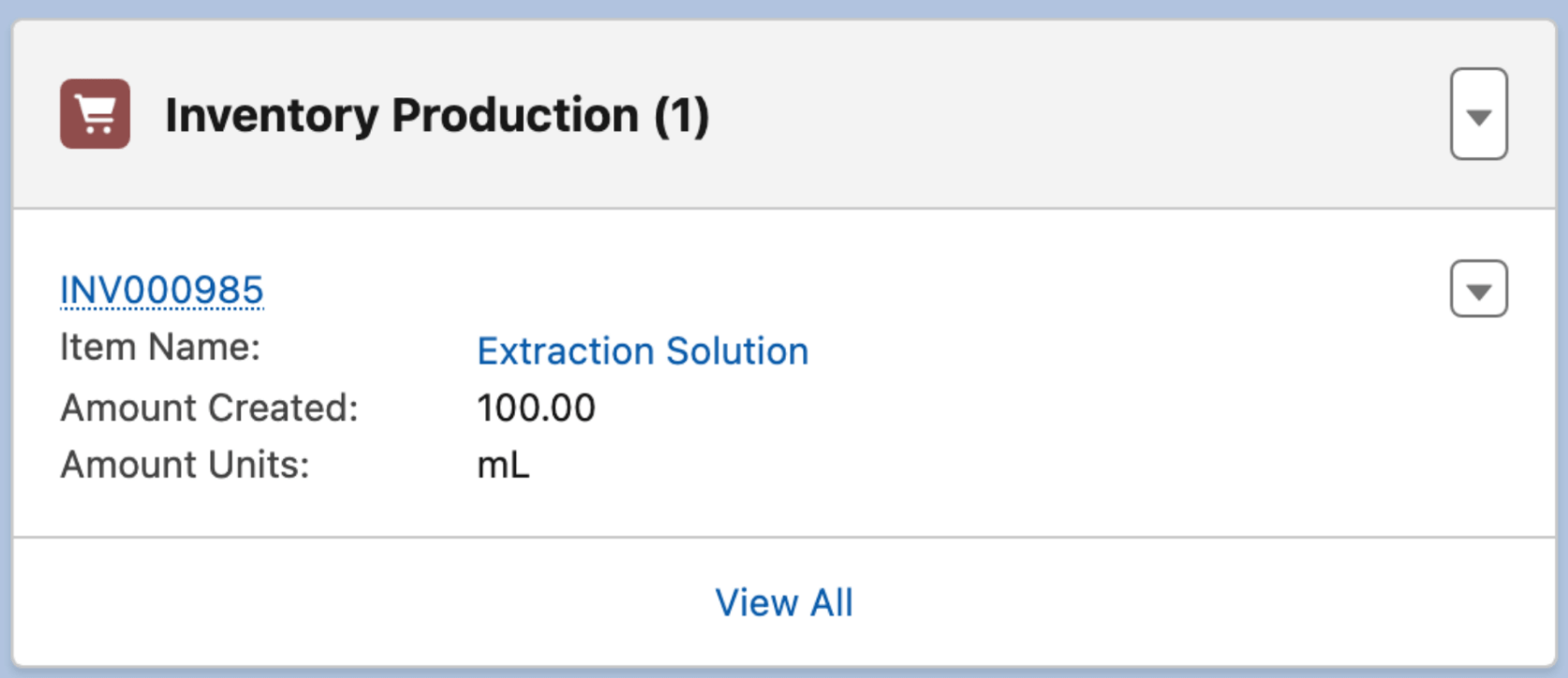

- Creation of New Inventory from Protocols

- Lockbox records the creation of new inventory, such as reagents or manufactured products, directly from protocols, which is crucial for manufacturing laboratories. This feature ensures that newly created inventory is automatically logged and available for future use or sale. Users can modulate the status of newly created inventory based on internal processes.

- Connection to Storage Management Module

- Connection to the Storage Management module provides users with visibility into the location of inventory items. Users can quickly identify the specific refrigerator, freezer, shelf, or rack where inventory is stored.

- Advanced Inventory Search Features

- The Find Inventory function searches Lockbox for the best available inventory to use in a Protocol. Lockbox automatically selects the best option based on expiration dates and/or partially used containers.

- Scan Inventory enables users to search for inventory by scanning a Barcode, Lot Number, ID, or other field. Lockbox then displays a list of required inventory and quantities for the protocol.

- Comprehensive Reporting Capabilities

- Lockbox has comprehensive reporting capabilities to simplify your inventory management. Users can quickly generate reports that display inventory metrics such as items on order and inventory expiration dates. Details are found in our Lockbox Inventory Management Comprehensive Feature Guide.

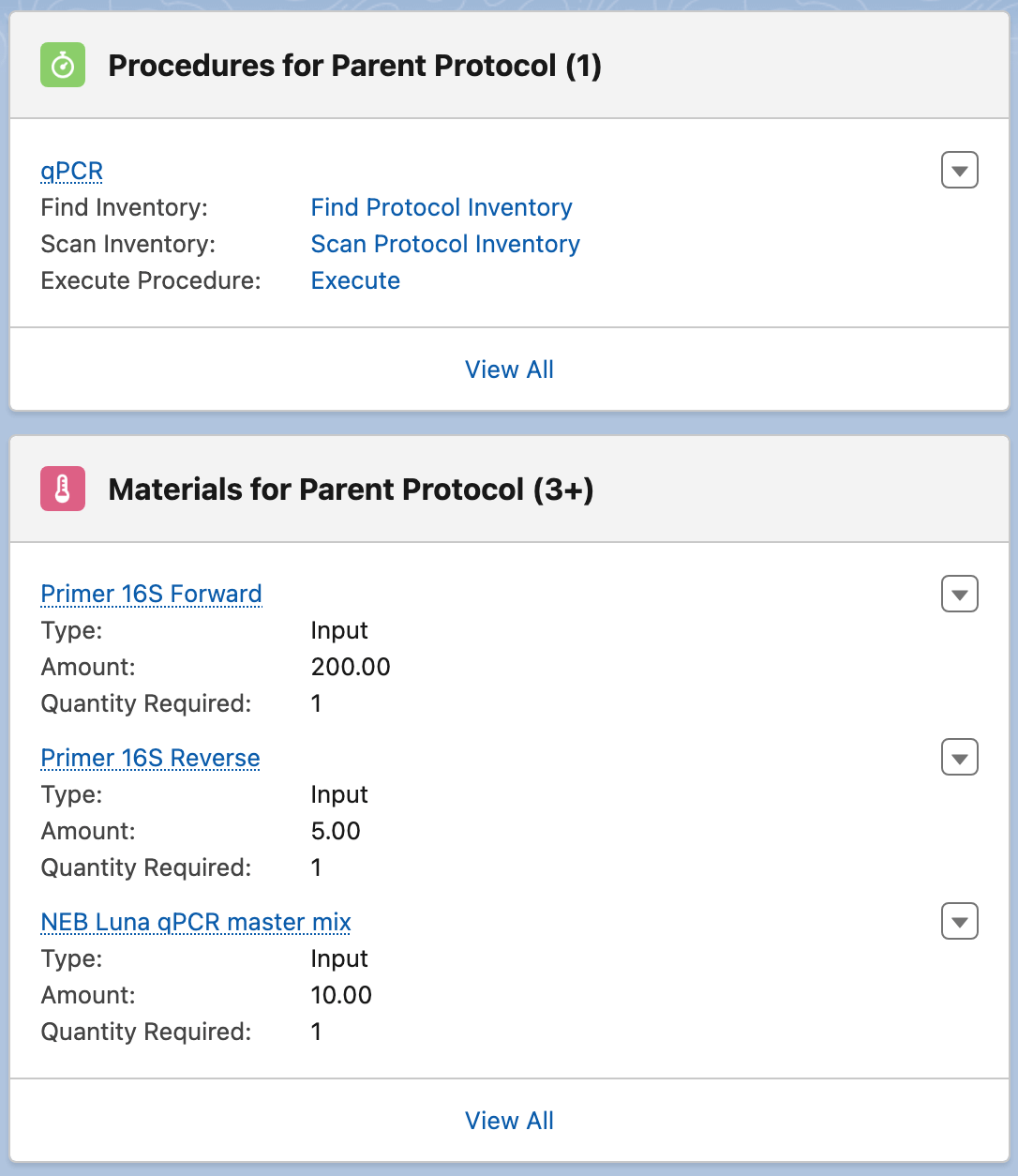

Optimized Protocol Execution

Lockbox Inventory Management and the Lockbox LIMS Protocol Execution module are tailored to your unique laboratory and workflows. Your implementation team will set up your workflows with the exact materials required for each protocol. This ensures that your lab technicians always know what is needed for each protocol.

- Customization of Material Usage and Creation

- Your implementation team will customize material usage or creation in your protocols and procedures.

- Lockbox can create a new inventory record when a protocol is completed.

- Automatic Material Identification

- Lockbox automatically identifies the materials and quantities required for each protocol, offering suggestions based on the best available options in your stock. Users can choose from Lockbox suggestions or select an alternative.

- Controlled Inventory Consumption

- After the protocol is completed, the inventory used within the protocol will be automatically marked consumed, so other users know it is no longer available. This feature reduces the risk of errors and ensures that inventory levels are always accurate.

- Real-Time Data Synchronization

- Inventory consumption or creation is logged automatically in real-time, allowing managers and laboratory staff to monitor inventory usage at any moment. This transparency supports better decision-making and resource management.

- Reduction in Human Error

- By automatically recording inventory reservation, consumption, and creation, Lockbox minimizes human errors associated with manual data entry. This leads to more accurate inventory records and simplifies physical inventory reconciliation.

- Control of Substances Hazardous to Health (COSHH)

- Lockbox Inventory Management allows users to print COSHH labels, mark chemicals and reagents as hazardous, and list equipment and precautions needed for using the item.

Flexible Protocol Configuration

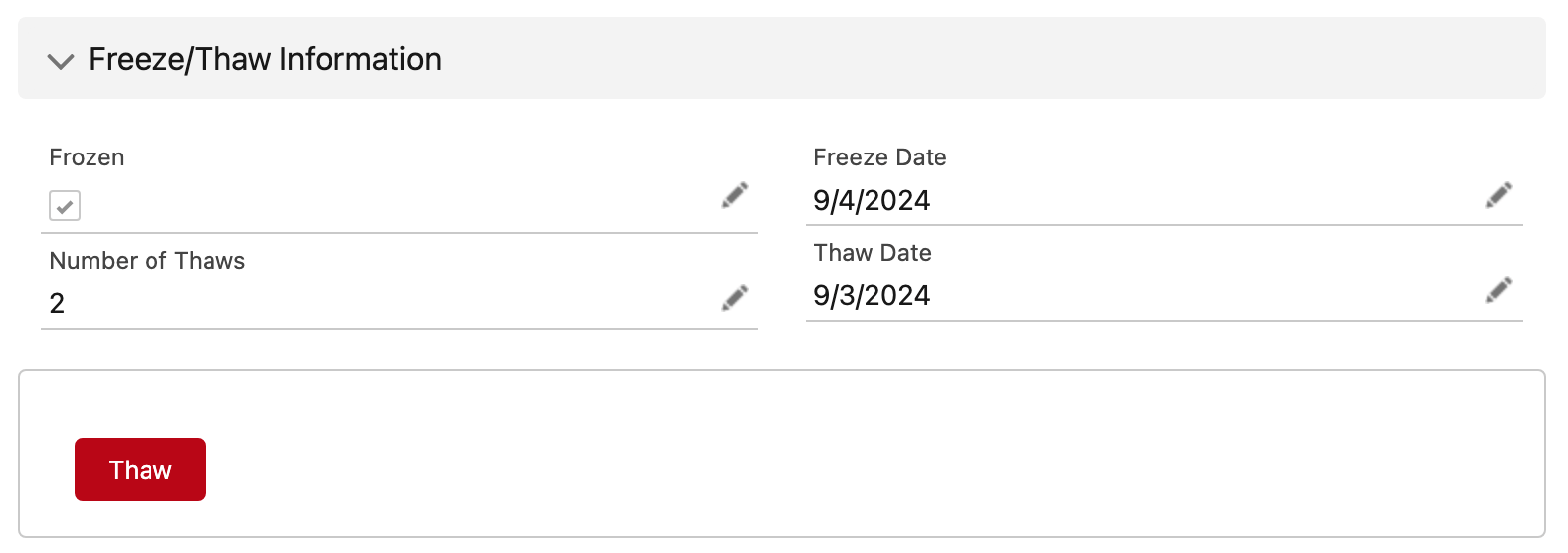

If you do not need such detailed inventory tracking and only want to capture lot numbers, that is easily done during protocol execution. Lockbox provides users with the ability to track freeze/thaw cycles and other reagent handling information. Having this knowledge readily available enables teams to troubleshoot problems quickly and efficiently, rather than sifting through information logged elsewhere or relying on memory.

- Capturing Lot Numbers Without Consuming Inventory

- A protocol can be configured to capture lot numbers but not consume inventory. This feature is useful for laboratories that do not require detailed inventory management.

- Cycle Counting and Tracking

- Lockbox can count and record the number of freeze/thaw cycles, helping users ensure the integrity and reliability of samples and reagents, leading to more accurate and reproducible experimental outcomes.

- The user can keep track of the freeze/thaw cycle of proteins and enzymes to prevent degradation and activity loss, which can lead to inaccurate experimental results.

- Handling History Documentation

- Tracking the history of reagents enables the user to correlate changes in experiment outcomes with any variability in handling cycles that can lead to inconsistent results.

- Recording freeze/thaw cycles provides a traceable history of the reagents, which is important for audits and reviews of the traceability history of reagents. Thorough documentation is necessary for regulatory compliance for labs following Good Laboratory Practices (GLP) or those involved in clinical or pharmaceutical research.

Enhanced Compliance and Traceability

With Lockbox you will always know who used or created inventory, in which protocol inventory was used, and which samples were processed with specific inventory. This enhanced traceability simplifies audit data collection, helping your laboratory be compliance-ready.

- Comprehensive Record-Keeping

- Lockbox Inventory Management’s real-time updates provide a complete and accurate view of inventory at any time, supporting comprehensive record-keeping and easy access to inventory data.

- Regulatory Compliance Support

- Lockbox Inventory Management supports your regulatory compliance and CAP/CLIA certification needs by ensuring up-to-date records of all inventory and by preventing the use of expired reagents by automatically removing them from the list of inventory available for the protocol.

- Easy Auditing and Reporting

- Lockbox simplifies the auditing process by providing easy access to inventory records and detailed traceability of reagent usage, making it easier to prepare for audits and ensure compliance.

Conclusion

Integrating Lockbox Inventory Management with Lockbox LIMS Protocol Execution module provides substantial benefits for laboratories, including streamlined processes, enhanced inventory management, optimized protocol execution, and improved compliance and traceability. By adopting this solution, laboratories can achieve greater efficiency, reduce errors, and ensure they always have the necessary inventory available for their protocols.

Contact us or reach out to your Engagement Director if you are ready to tap into the capabilities of Lockbox Inventory Management and Lockbox LIMS Protocol execution.